- Top: 73365Step on: 3629

pengudaraan kimpalan

People involved | Date:2025-08-14 05:10:58

Related articles

Perhaps most crucial is the trustworthiness of automatic spray coating machines

. Users seek equipment that not only performs effectively but also maintains safety and environmental standards. Modern machines are designed with built-in filters and eco-friendly components to reduce pollutants. This emphasis on health and environmental safety enhances trust among consumers and businesses alike. Moreover, manufacturers provide extensive warranties and reliable customer support, addressing potential concerns promptly and ensuring long-term satisfaction with their investment.- Certification and Compliance Ensure that the manufacturer complies with relevant industry standards and certifications, such as ISO or environmental regulations, which can affect your operations.

An authoritative aspect of automatic spray painting machines is their contribution to environmental sustainability. With stringent regulations on emissions and waste, these machines address ecological concerns by minimizing overspray and utilizing eco-friendly coatings. This not only helps companies comply with global environmental standards but also promotes corporate responsibility towards sustainable production practices.

4. Noise Levels Consider the noise produced by the extractor, as excessive noise can be distracting and contribute to a stressful working environment.

Mobile Welding Fume Extractor

The Role of Portable Welding Fume Extractors in Cleaner Manufacturing

5. Environmental Considerations Containers must also comply with environmental regulations, including those regarding hazardous materials. The survey must ensure that containers transporting such cargoes meet specific safety guidelines to prevent pollution and accidents.

Lastly, the size and portability of the unit should align with the workspace layout. A compact design may be ideal for smaller areas, while larger models might be suitable for bigger factories or workshops.

Conclusion

4. Specialty Rods Specialty rods, including those for aluminum or high-temperature applications, cater to specific needs. Aluminum rods are designed for welding aluminum and its alloys, and high-temperature rods are used in situations that require heat resistance.

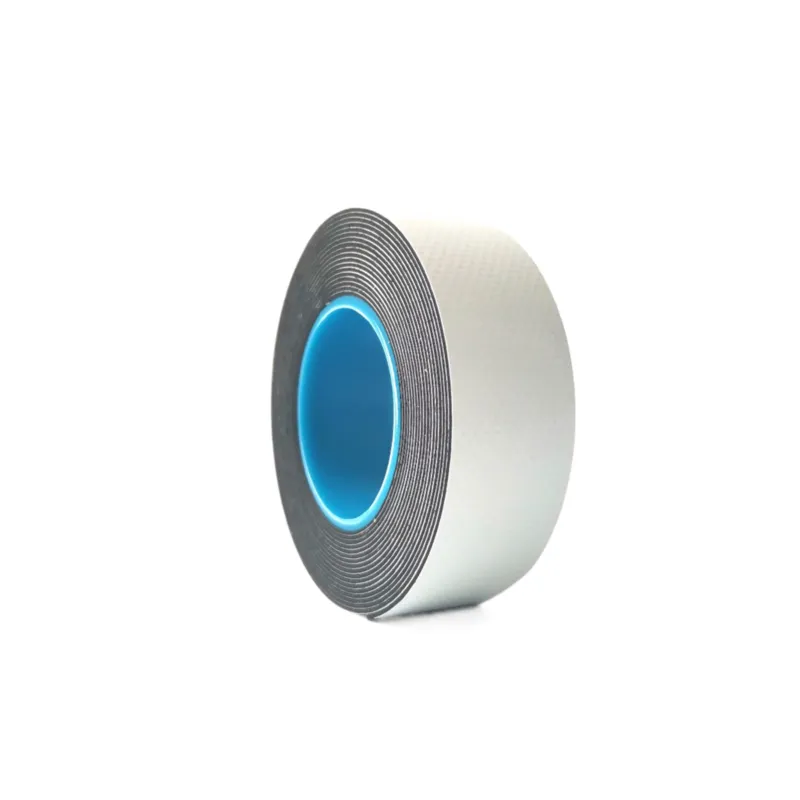

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems

As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems

This not only ensures public safety but also fosters a sense of order and responsibility among patrons This not only ensures public safety but also fosters a sense of order and responsibility among patrons

This not only ensures public safety but also fosters a sense of order and responsibility among patrons This not only ensures public safety but also fosters a sense of order and responsibility among patrons

Comment area